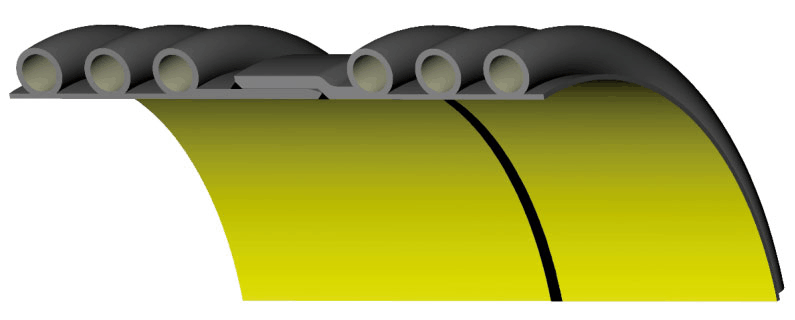

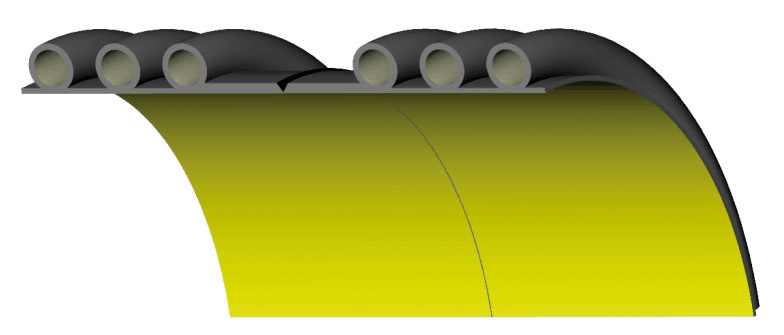

Most Krah pipes are produced with an integrated socket and spigot.

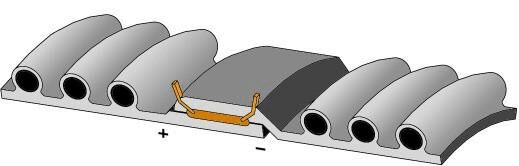

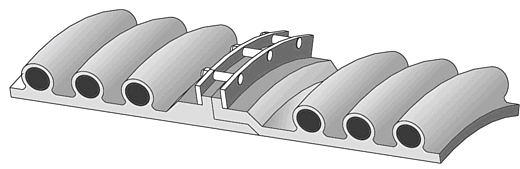

These are adaptable to the following listed jointing technologies. As various tests and decades of experience have shown, the jointed part of a pipe system is usually the most vulnerable part. Here, the pipe is mostly exposed to possible leakages. The Krah system offers a well-bbbknown connection method developed further for large scale application which eliminates these concerns by guaranteeing a solid homogenous pipe line.

The Krah group offers a modern sewer pipe program with manholes, fittings, and safe pipe joint systems for the planning of sewer treatment plants.

Gravity Pipes made out of PE80 / PE100 and polypropylene can have inner diameters ranging from DN/ID 300 mm to DN/ID 5000 mm. The standard length of 6m enables easy transport, quick handling and less jointing.