Social Media

Social Mediafrom a business kind of view

Krah Pipes

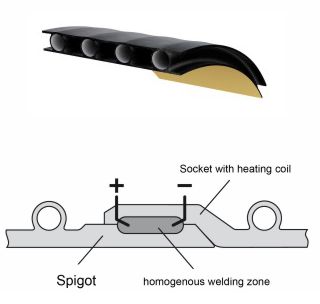

In July this year, we recorded our 1000th subscriber on YouTube. So our increased engagement on the LinkedIn, Instagram and YouTube platforms seems to be paying off! Especially with our new support Alannis and her new format “Alannis asks” we were able to gain a whole new set of followers and interactions. We currently have the most followers on our Instagram account @derkrah - a whole 1400 people follow us there. 70% of them are men, mostly between 18 and 40 years old. Most of them come from Germany, the USA and Brazil. On LinkedIn, the more business-oriented platform, we currently have 1300 followers on @KrahPipes, especially after every trade fair the number goes up. There we have a “Krah Community” group in which every customer is a member. Information is exchanged and in the case of more specific questions or problems, there is always a lively exchange and suggestions for solutions. On our YouTube channel @KRAH, theory then becomes practice: our technology, which is explained in brochures and on our homepage, becomes tangible there. In various practical episodes, we take viewers to construction sites or other branches, explain the Electrofusion technology or carry out experiments to show the extraordinary loads our pipes can withstand. This is also where Alannis is at home, producing weekly videos and providing insights and explanations. Marketing, Krah Group

In order for us to see how well the videos are received by you, what we could possibly do well or better, or what suggestions or video wishes you have, it is important that you subscribe to our “KRAH” channel, give the videos a “Thumbs up” or comment on them - the algorithm of the various platforms works in such a way that interactions are everything. Especially on YouTube, where it takes several hours to edit and finish a video, it is important that you give us feedback to see if we can continue or change something - adapted to your questions and suggestions.

We think that Social Media has become a part of our daily life, and even in business environments it can be an extremely helpful tool to be closer to the customer, to make things more explainable and to have an easier way of communication. Even requests are made through comments or direct messages on these platforms - think about yourself, would you prefer just quicly sending a request through a direct short text message or preparing a long mail, which mostly has to be done on a computer or laptop?

Even personnel recruitment can work through Social Media, by posting your job offer on the “Gram”.

So please make sure to stay active on our channels and keep being so supportive, it means a lot to us!

Lisa & Jenny

.